Unlike conventional noise absorbers or energy harvesters, these meta-stacks (including designs like helical porous stacks and pie-slice resonators) bring a leap forward in capability. The device consists of a resonant chamber (resonator), a specially designed porous stack inside it, and built-in thermoelectric elements forming a Thermocouple.

As sound waves enter the resonator, the helical-shaped pores in the stack force the acoustic energy to interact over a longer path, efficiently converting sound into minute temperature differences. The pie-slice resonator geometry further improves performance by channeling sound waves directionally and minimizing interference between acoustic modes. In essence, TAMS is a multifunctional acoustic metamaterial – it absorbs and dampens low-frequency noise while simultaneously transforming that acoustic energy into heat and then electricity.

This technical breakthrough builds on cutting-edge acoustic metamaterials research and thermoacoustic engineering. The helical pore stack design offers a compact yet effective way to handle low frequencies (which are typically the hardest to absorb with traditional soundproofing). By coiling the channels in a spiral, we achieve greater interaction between sound and material without requiring a huge device. According to our studies, this spiral stack approach enables precise control of how sound waves propagate and greatly improves heat transfer efficiency for energy conversion.

Meanwhile, the integrated thermopile (an array of thermoelectric transducers) directly converts the induced temperature gradient into electrical power. Importantly, the system has no moving parts – increasing its durability and reducing maintenance needs compared to legacy solutions like piezoelectric harvesters. Overall, the TAMS design is a fusion of acoustics and energy science: it’s part noise-canceller, part power generator.

Real-World Impact: Quieter Communities, Greener Energy

The real-world benefits of TAMS are as exciting as the engineering. Low-frequency noises – the deep engine rumbles and subway vibrations that traditional absorbers struggle with – are a prime target for this technology. In a feasibility study, our TAMS prototype achieved a noticeable 5+ dB reduction in sound at around 118 Hz (a typical low-frequency rumble) while simultaneously generating a measurable electrical output. That means a significant drop in one of the most persistent, hard-to-muffle noise ranges, turning what was once just pollution into a useful energy source.

Noise reduction isn’t just about comfort – it’s about health and environmental quality. Excessive noise has been linked to stress, sleep disturbances, and even cardiovascular issues. By cutting down ambient noise in urban environments, TAMS can improve quality of life for city dwellers and for neighborhoods near airports, highways, or industrial sites. There’s an environmental angle too: noise is considered a form of pollution, and mitigating it helps create more livable cities. At the same time, the energy harvested from these sound waves, though modest, is clean and essentially free – it’s energy that would otherwise be wasted. For instance, the electricity generated by a TAMS noise-barrier along a highway could power nearby sensors or LED streetlights, enhancing energy efficiency in infrastructure.

We have already begun putting TAMS to the test in real-world scenarios. With support from the Federal Aviation Administration (FAA), we carried out a pilot demonstration at Dallas/Fort Worth International Airport (DFW) to target the droning roar of runway traffic. The TAMS unit was able to dampen low-frequency runway noise, validating its potential in an airport setting.

The promising results from that trial have opened doors for further implementations – including interest from the New York City subway system. If deployed in a subway tunnel or station, TAMS panels could significantly lower the noise for commuters and trackside workers while generating power from the constant clatter of trains. It’s a rare win-win: quieter subways and airports, plus a bit of extra green energy on the side.

Commercialization and Future Applications

Moving from lab prototype to real-world product, TAMS demonstrates immense commercialization potential across multiple industries. The technology’s dual functionality—simultaneous noise reduction and energy harvesting—addresses critical challenges that aerospace manufacturers like Boeing are actively working to solve through their NASA partnerships. Boeing’s ongoing collaboration with NASA on acoustic liner technologies, including their recent 787-10 eco Demonstrator test program that utilized over 200 noise sensors to advance aircraft noise prediction capabilities, demonstrates the industry’s urgent need for innovative acoustic solutions.

Similarly, transportation authorities such as the New York City Metropolitan Transportation Authority (MTA) are investing heavily in acoustic improvements for their infrastructure. Recent MTA projects incorporate sound-absorbing treatments at stations like the 96th Street Second Avenue Subway, where acoustic materials are strategically placed to reduce both train noise and improve passenger announcement clarity. These ongoing industry initiatives underscore how broadly applicable TAMS technology could be, particularly given its unique ability to convert problematic noise into useful energy.

Boeing’s interest in such technologies points to natural applications in aerospace—integrating TAMS into aircraft engine liners or fuselage panels could simultaneously reduce cabin noise and recover energy in the acoustically challenging environments of air travel. The aerospace industry’s growing focus on electric aircraft and sustainable aviation technologies creates additional opportunities for energy-harvesting acoustic solutions that could support auxiliary power systems while improving passenger comfort.

I am also excited to share that we are in the process of launching a startup, Quiet Power, to bring this innovation to market. Quiet Power will focus on developing TAMS-based solutions for various industries, and we’re already envisioning a range of potential applications:

This vision is no longer just theoretical. As of 2025-06-19, the core innovation behind Quiet Power has officially been published as an international patent under the title “Thermoacoustic Metastructure Devices and Methods” (Patent Publication No. WO2025128348A1). This milestone moves the technology from patent-pending to formally recognized intellectual property — a critical validation of its novelty, utility, and global significance. The publication not only protects the unique meta-stack geometries and acoustic-to-energy conversion mechanisms at the heart of TAMS, but also signals to industry and investors that this is a commercial-ready platform with transformative potential across multiple sectors. The full patent is now available through WIPO, offering technical insights into how this technology combines engineered acoustic pathways, thermal gradients, and additive manufacturing to create the first multifunctional system of its kind. In short, Quiet Power has passed the point of speculation — it’s a patented innovation, and it’s ready to reshape how we think about waves, noise, and power.

Industries Poised to Adopt TAMS First

Environmental noise pollution is more than a mere annoyance – it is a serious health and economic issue. In Europe alone, over 110 million people are exposed to harmful noise levels, leading to stress, sleep disturbances, 66,000 premature deaths each year, and tens of thousands of cases of heart disease and other illnesses. The economic burden is staggering, with noise-related health impacts costing an estimated €100 billion annually in Europe. Addressing this challenge requires innovative solutions that not only quiet the noise but also recapture its wasted energy. One such breakthrough is a patented thermoacoustic metastructure (TAMS) – the technology described in WO2025128348A1 – which can turn acoustic pollution into a usable power source. This invention operates by using specially engineered acoustic resonators and thermoelectric elements to convert sound waves into electricity while simultaneously dampening the noise. In essence, it transforms the unwanted hum of our cities and industries into a “symphony of energy,” converting nuisance noise into valuable clean power. Below, we explore how this acoustothermo-electric innovation works and its far-reaching implications across industries, economic and energy systems, and how it compares to existing technologies.

- Transportation Infrastructure: The TAMS invention is poised to revolutionize how we manage traffic and airport noise. Highways, rail lines, and runways flanked by thermoacoustic metastructure panels could not only mute the roar of engines and tires but also harvest that acoustic energy into electricity. For example, a highway noise barrier built with this technology would protect nearby neighborhoods from excessive noise and generate power to run street lights or charging stations. Noise pollution hot-spots near roads and airports – once merely an annoyance – can thus become sites of energy production, giving a positive return to neighboring innovations. This patented approach effectively recycles the din of transportation into a resource, aligning with smart-city initiatives and sustainable infrastructure goals.

- Urban Buildings & Construction: In cities, where space is at a premium and noise complaints are common, thermoacoustic metastructures can be integrated into building materials and facade elements. Imagine apartment high-rises or office buildings with walls that double as soundproofing and power generators. The technology described in the patent can be embedded in architectural panels to absorb street noise and convert it to electricity for the building’s use. This not only improves indoor comfort by cutting down on external noise but also contributes to the building’s energy supply. By harnessing additive manufacturing, researchers have envisioned sculpting TAMS into lightweight, modular components that fit within walls and sound barriers. The result is quieter, more energy-efficient buildings – a boon for construction and urban planning sectors aiming for green and livable cities.

- Industrial Facilities: Factories and power plants are often sources of loud mechanical noise. Implementing the TAMS invention in these settings means capturing industrial noise at its source. Acoustic metastructure units could line the walls of a manufacturing plant or surround noisy machinery, performing double duty: protecting workers and nearby communities from harmful noise, and generating supplemental power from the sound vibrations. Industries such as manufacturing, mining, and energy (e.g. around turbines or compressors) stand to benefit by recovering energy from what is currently wasted sound. Moreover, reducing noise levels can improve worker safety and communication on the factory floor. The durability and resilience of the thermoacoustic modules make them well-suited for harsh industrial environments, where traditional delicate electronics (like many piezoelectric devices) might fail. By converting noise to electricity on-site, industrial operators could offset power for sensors, lighting, or even feed it back to the grid, turning compliance with noise regulations into an opportunity for energy savings.

- Aerospace & Aviation: Aircraft and spacecraft present unique use-cases for this technology. In aviation, aircraft engines and airframe components produce significant noise; embedding TAMS-based liners or panels in jet engine nacelles or fuselages could help muffle engine noise while scavenging some of that acoustic energy to power onboard systems. This could be especially useful for more-electric or hybrid aircraft, where every bit of harvested energy can improve efficiency. At airports, thermoacoustic metastructures could line runways or sound barriers around the perimeter, generating power from the thunder of takeoffs and landings. Even beyond Earth, researchers note the potential for thermoacoustic metastructures to exploit extreme conditions – for instance, using acoustic or thermal gradients in spacecraft. The invention’s principles can be applied to space probes or satellites, where large temperature differences or mechanical vibrations (from onboard equipment) could drive a thermoacoustic process and produce electricity. Indeed, the early concept dubbed “Quiet Power” demonstrated that mechanically robust thermoacoustic harvesters could power sensors in remote locations “from oil pipelines to space probes,” showcasing the versatility of this approach even in the vacuum of space (using internal gas media). The aerospace industry, always seeking reliable, lightweight, and maintenance-free power sources, could integrate this technology for noise reduction and energy recovery in everything from passenger jets to deep-space exploration vehicles.

- Remote IoT Sensors & Utilities: A major challenge for the Internet of Things (IoT) and remote monitoring systems is providing power to countless sensors distributed in the field. This patented thermoacoustic energy harvester offers a solution by tapping into ambient acoustic or thermal energy where solar or grid power may be insufficient. For example, consider sensor networks along oil pipelines, inside HVAC ducts, or on heavy machinery: these environments often have a constant rumble or vibrations. TAMS devices can convert those vibrations and noise into electrical power, recharging batteries or even removing the need for batteries altogether in wireless sensors. This dramatically reduces maintenance costs (no frequent battery replacements in hard-to-reach areas) and improves reliability for critical monitoring of infrastructure. Likewise, in urban environments, smart city sensors placed near traffic or industrial sites could use the very noise they monitor as an energy source. By reducing or eliminating the need for dedicated power infrastructure for sensor networks, the invention enables more scalable and sustainable IoT deployments. From environmental noise monitoring stations to structural health sensors on bridges (which experience vibrations), the applications in the sensor and utility domain illustrate how waste acoustic energy can empower the next generation of smart systems.

Economic Impact

Implementing this thermoacoustic metastructure technology carries profound economic implications. Firstly, it turns noise reduction from a cost center into a source of value. Traditionally, money spent on noise mitigation (like building sound barriers or insulating homes) yields no direct financial return – it’s an expense for compliance or community comfort. In contrast, a TAMS-equipped noise barrier or panel pays back over time via energy generation. The electricity produced by traffic noise or industrial hum can offset facility power usage or even be sold back to the grid. This creates a new revenue stream or savings mechanism for infrastructure operators and municipalities. As noted by researchers, noise pollution byproducts of urban life “now have a positive return for neighboring communities” when using such energy-harvesting. In essence, the invention changes the ROI equation for projects that combat noise, encouraging more investment in noise-control measures because they can eventually pay for themselves.

Secondly, there are direct savings in operational costs. By generating power from ambient noise, facilities can reduce their purchased electricity needs. For example, a factory that recycles its machine noise into powering its sensor network or emergency lighting will see lower energy bills. Over a large scale – say a highway stretch with miles of TAMS noise barriers – the cumulative energy could be substantial, offsetting the electricity for roadway lighting or signage. This contributes to energy cost savings and resilience, as local generation can buffer against grid fluctuations.

Furthermore, the broader economic benefit includes healthcare and productivity gains due to noise reduction. Excessive noise has been linked not only to health issues but also to lost productivity (from sleep disturbance, stress, etc.). By mitigating noise, communities may experience improved well-being and productivity, which has economic value (a European study quantified noise-related health costs around €100 billion per guardian.com). The thermoacoustic metastructure thus offers indirect economic benefits by potentially reducing these external costs – healthier, more productive populations and less strain on healthcare systems.

To highlight key economic impacts of this innovation:

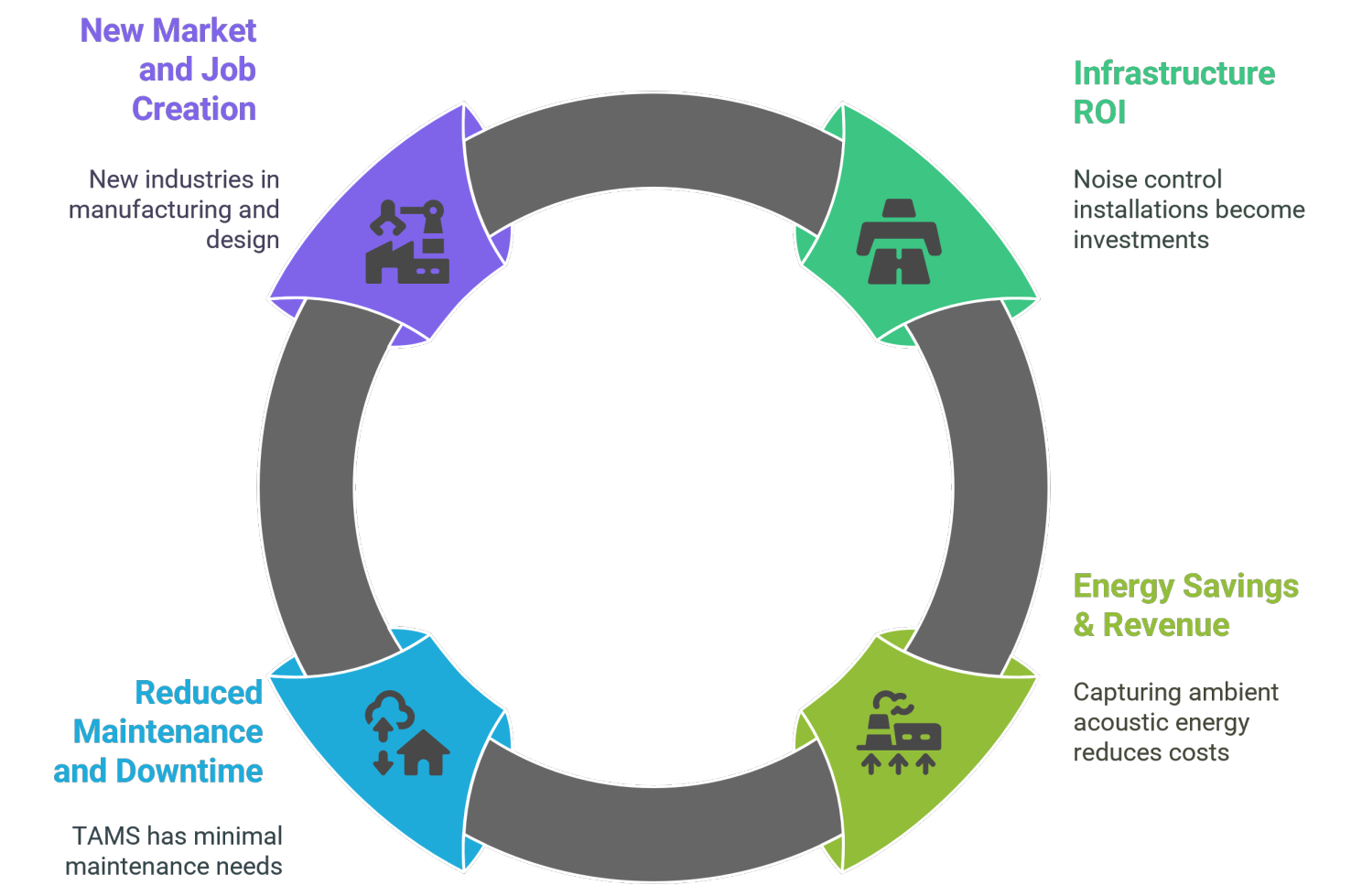

- Infrastructure ROI: Noise control installations become investments rather than sunk costs. For instance, a city spending funds on highway sound barriers could recoup the expense through energy generation over time. This dual-purpose functionality may attract public funding and private partnerships, as the barriers effectively pay dividends in the form of renewable energy.

- Energy Savings & Revenue: Capturing ambient acoustic energy reduces the amount of electricity that must be bought or generated by other means. Facilities or grid operators save on energy costs, and any excess power can be fed into the grid for revenue or credits. Over years of operation, these savings accumulate significantly, improving the economic feasibility of projects.

- Reduced Maintenance and Downtime: Because the TAMS has no moving parts and minimal maintenance needs, life-cycle costs are low. Compared to generators or even batteries that require periodic replacement, these devices can operate for long periods without intervention. This is economically advantageous for remote deployments (saving labor costs for battery changes or generator refueling) and for industrial settings where downtime is costly.

- New Market and Job Creation: As this technology moves from lab to market, it could spawn new industries in manufacturing thermoacoustic panels, retrofitting existing structures, and specialized design services. This innovation sits at the intersection of renewable energy and noise control – sectors that are both growth areas. Companies licensing the patent or developing spin-offs could create high-tech jobs and supply chains focused on acoustic energy harvesting. In the larger picture, it contributes to the green economy, valuing previously ignored resources (noise) as economic assets.

Energy Efficiency and Sustainability

From an energy efficiency standpoint, the thermoacoustic metastructure represents a clever energy recycling mechanism. It exploits the fact that a significant amount of energy in our environment dissipates as unwanted sound and heat. By capturing and converting a portion of that lost energy into electricity, the overall efficiency of systems and environments is improved. This technology is essentially harvesting “free” energy that would otherwise go unused, thereby increasing the energy efficiency of an industrial plant, a transportation system, or a building. Every watt scavenged from noise is a watt of primary energy saved elsewhere. In a world pushing for net-zero and sustainability, such incremental gains – multiplied across many installations – contribute to the renewable energy mix without needing additional fuel or land (unlike, say, solar panels or wind turbines, which require dedicated space). Here, the energy source is a waste byproduct of existing activities, making it exceedingly sustainable.

Technically, the TAMS device is engineered for optimal energy conversion. At its core is a porous stack (a specially designed material structure with tiny channels) mounted inside a resonant acoustic chamber. When noise (pressure fluctuations in air) enters the resonator, it causes air oscillations through the porous stack. Thanks to the thermoacoustic effect, these oscillations induce a temperature gradient across the stack: air parcels repeatedly compress and expand, heating on one side and cooling on the other. The patented design places a thermopile – an array of thermoelectric transducers – in contact with the stack at strategic locations to capture this temperature difference. The thermopile then converts the heat differential directly into electrical energy (via the Seebeck effect). All of this happens with no moving pistons or turbines, relying only on solid-state physics and clever geometry. Such a design means virtually no frictional losses or mechanical wear-and-tear, which is a major efficiency and reliability advantage over conventional kinetic energy harvesters. As researchers note, leveraging thermoacoustic phenomena in this way enables efficient energy conversion, especially for low-frequency noise that other methods struggle with. Low-frequency sounds (like a distant rumble or heavy machinery drone) carry a lot of energy but are hard to absorb and convert using small piezoelectric devices; a resonator-based TAMS can be sized and tuned to these frequencies, addressing this challenge head-on.

Another aspect of efficiency is that TAMS performs two functions in one unit – noise reduction and power generation – which is inherently efficient in terms of material and space use. Instead of separate systems (one to absorb sound, another to generate energy), a single integrated system accomplishes both. For example, conventional acoustic foam in a wall simply converts sound to a tiny bit of heat that disperses; by contrast, a thermoacoustic metastructure panel converts sound to heat and then immediately to electricity. Essentially, it closes the loop on the energy conversion process. This multi-functionality means that any energy used to mitigate noise is not wasted but reclaimed, pushing the effective efficiency of noise control measures higher than ever before.

It’s worth noting that this technology is still advancing through prototyping and optimization. In proof-of-concept tests, a small thermoacoustic metastructure unit demonstrated tangible results: a noise level reduction of about 5.3 dB at the target frequency (significantly lessening the perceived loudness) and simultaneously generating a measurable electrical output. The initial prototypes produced modest voltages (on the order of a few dozen millivolts) under lab conditions – a promising start given the early stage. With further engineering (e.g. scaling up the resonator size, using more efficient thermoelectric materials, and optimizing the stack geometry), these figures can improve. Moreover, because multiple TAMS modules can be arrayed together (much like solar panels in a farm), their collective output can add up. The energy conversion efficiency of each module is expected to be higher than many existing acoustic harvesting methods, thanks to the tuned resonance and thermal coupling design. And importantly, all this is achieved with minimal maintenance: the lack of moving parts and the use of solid-state thermoelectrics mean the system can operate continuously with little performance degradation. This reliability further contributes to operational efficiency, as downtime or energy losses due to maintenance are kept to a minimum.

In terms of sustainability, beyond just energy metrics, the materials and operation of TAMS are environmentally friendly. It generates clean power without emitting any pollutants – essentially converting noise (which is a form of pollution itself) into electricity with zero greenhouse gas emissions. By offsetting grid electricity (which might come from fossil fuels in some regions), it indirectly cuts emissions as well. Additionally, the invention can utilize advanced manufacturing techniques like 3D printing (additive manufacturing) to create the intricate porous stacks. This allows for efficient use of materials and the possibility of recycling or using novel sustainable materials in construction of the device. The long service life and maintenance-free nature mean fewer replacements and less waste over time. All these factors make the thermoacoustic metastructure an appealing technology in the context of sustainable engineering and circular economy principles – it finds value in waste (noise) and has a benign operational footprint.

Comparisons to Existing Tech

It is illuminating to compare this thermoacoustic metastructure (TAMS) approach to other existing technologies aimed at either noise mitigation or energy harvesting, to appreciate its unique advantages:

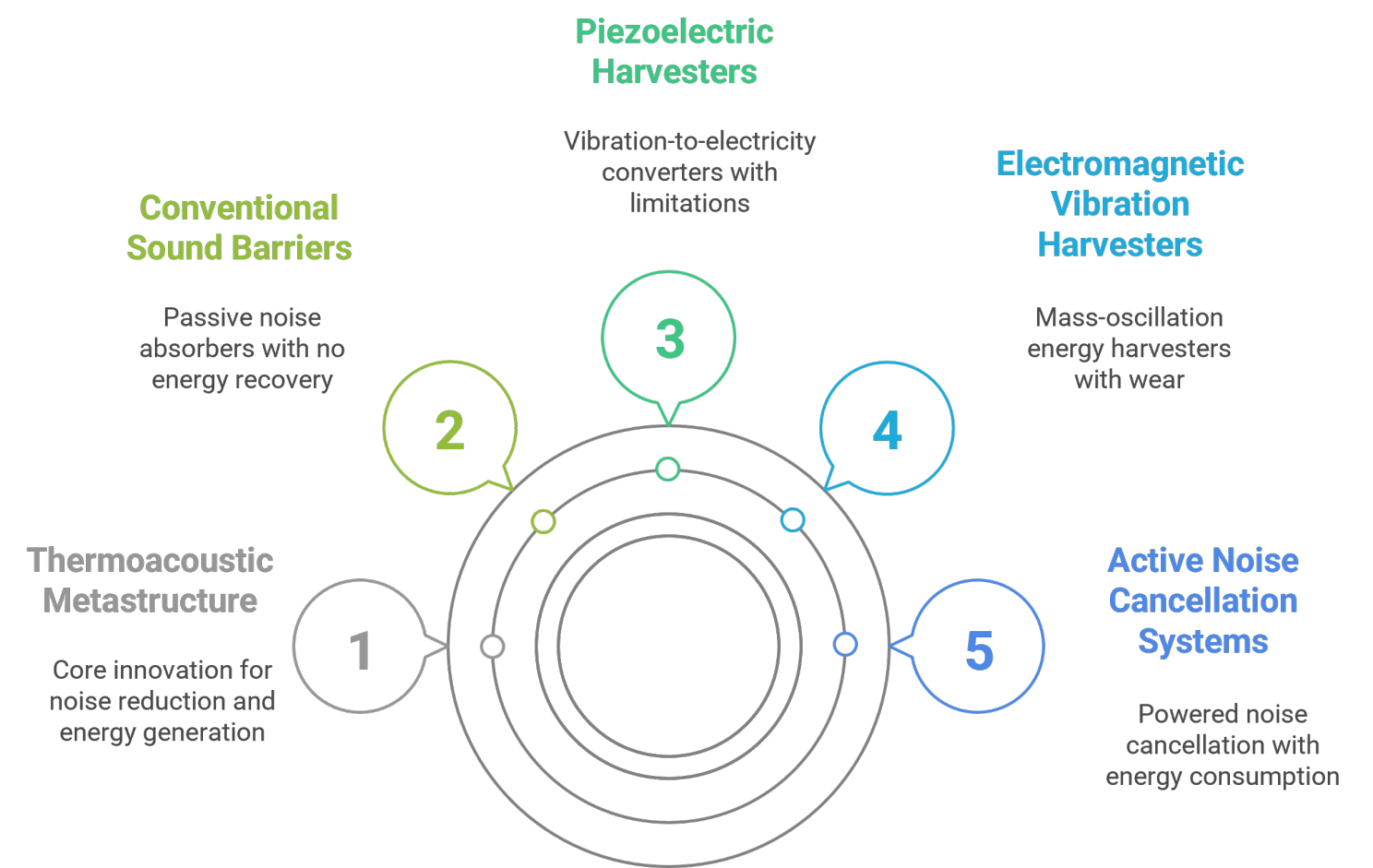

- Versus Conventional Sound Barriers: Traditional noise barriers (e.g. concrete walls along highways, acoustic drywall in buildings) are passive absorbers – they block or absorb sound but do not recover any energy. The sound energy is typically dissipated as trivial amounts of heat in the material, and the barrier’s sole benefit is noise reduction. In contrast, a TAMS-based barrier both reduces noise and generates electricity. This dual function means that unlike conventional barriers which are pure expense, TAMS barriers create value. As noted, they turn noise into a “positive return” opportunity rather than just a problem to be managed. Additionally, conventional barriers often need to be large and heavy to block low-frequency noise, whereas the resonator-based design of TAMS can be tuned to target those frequencies more efficiently, potentially allowing for lighter or more compact installations. In summary, the invention brings a paradigm shift: noise control infrastructure becomes a part of the renewable energy infrastructure at the same time.

- Versus Piezoelectric Harvesters: Piezoelectric devices are a common method for converting vibrations or acoustic waves into electricity. They work by stress in a crystal producing a voltage. While useful in some scenarios, piezoelectric harvesters face significant limitations in the context of environmental noise. They typically operate efficiently in narrow frequency bands and often at high frequencies, and their energy output for diffuse, low-frequency noise is very low. Known piezoelectric and electromagnetic acoustic energy techniques “suffer from low energy conversion efficiency” and high costs for what they produce. For example, harvesting sound from traffic noise using piezo panels might yield only microwatts of power in practice, not enough for meaningful applications unless scaled to impractical areas. Furthermore, piezoelectric materials can be brittle and degrade over time, especially under constant vibration, raising durability concerns. By contrast, the thermoacoustic metastructure is designed for robustness and higher efficiency in capturing acoustic energy. Its energy conversion involves a thermodynamic process rather than direct mechanical strain, which can be more suitable for the broad spectrum of noise frequencies. The patent’s inventors specifically highlight superior performance in energy capture and durability compared to conventional piezoelectric materials. Also, TAMS can target low-frequency noise (the hardest for piezos to handle) by adjusting resonator dimensions, addressing a gap where piezo solutions are mostly ineffective. In terms of maintenance, piezo systems might require periodic tuning or replacement, whereas TAMS’s solid-state thermopile and sturdy stack are built for longevity with minimal upkeeping.

- Versus Electromagnetic Vibration Harvesters: Another existing approach uses small electromagnetic generators (a coil and magnet system) to convert vibrations into power. These are common in some vibration energy harvesting (like on bridges or machinery) but typically involve a moving mass that oscillates. They tend to be bulky if designed for low-frequency (since a certain mass and spring are needed) and can suffer wear or require careful tuning to the vibration frequency. They also usually harvest energy from structure-borne vibrations rather than airborne sound, limiting their use in open-air noise scenarios. In comparison, the thermoacoustic metastructure has no moving masses at all – the “motion” is in the oscillating air and the heat flow, not a mechanical part – thus avoiding mechanical fatigue and friction losses. TAMS devices can be made relatively flat and integrated into surfaces, whereas electromagnetic units often need space to oscillate. While electromagnetic harvesters might achieve decent efficiency at a resonance, they often cover a narrow band and can be detuned by environmental changes. The TAMS, leveraging acoustic resonance in a controlled chamber, can be engineered to be adaptive or broadband (for example, by using multiple resonator chambers targeting different frequencies, or leveraging acoustic metamaterial concepts to widen the absorption band). This gives it an edge in harvesting energy from noisy environments where the sound spans various frequencies.

- Versus Active Noise Cancellation Systems: Though not an energy technology, it’s worth noting how TAMS compares with active noise control, which is another method to address noise pollution. Active noise cancellation (ANC) involves using powered devices (speakers emitting counter-phase sound) to cancel out noise. ANC consumes energy to drive the speakers and requires complex control systems. It is effective in some settings (like headphones or aircraft cabins) but impractical for large-scale outdoor noise like highways due to power and feedback constraints. The thermoacoustic metastructure, on the other hand, is a passive solution – it needs no external power to cancel noise (apart from the noise itself) and instead produces power. This flips the script: instead of expending energy to eliminate noise, it absorbs noise energy and turns it into useful power. While ANC is an active add-on that can fail if power is lost, TAMS is inherently fail-safe (at worst, if something stops working, it behaves like a normal absorber). Thus, in scenarios where one might consider active cancellation (e.g. to quiet a transformer hum or a ventilation system noise), replacing or augmenting it with a TAMS device could achieve noise reduction and yield energy, improving overall system efficiency.

In summary, this patented thermoacoustic metastructure stands out against existing technologies by combining the strengths of noise mitigation and energy harvesting into one resilient package. It leverages principles of acoustics and thermodynamics to overcome the efficiency limitations of piezoelectric and electromagnetic harvesters, and it transforms what was previously a waste (unwanted sound) into a resource. As development continues, it’s conceivable that we will see these TAMS panels alongside solar panels and wind turbines as a complementary form of renewable energy – one that additionally makes our living and working environments quieter. By addressing the long-neglected overlap between noise control and energy efficiency, the invention described in WO2025128348A1 paves the way for a future where “quiet” infrastructure also means productive infrastructure, contributing to both environmental tranquility and sustainable power generation. The vision is indeed professional and bold: cities and industries can be reimagined where every rumble and roar is an opportunity for energy, and where solving a pollution problem directly yields a clean energy benefit. This thermoacoustic metastructure encapsulates that visionary ideal – engineering a world that is both quieter and more powered, thanks to innovation that hears opportunity in every sound.

Join Us in Turning Noise into Opportunity

The journey for Thermoacoustic Meta-Structures is just beginning, and I invite you to be a part of it. Whether you’re a researcher, an industry professional facing noise challenges, or an investor in sustainable tech, let’s connect. Collaboration and fresh perspectives are key to taking TAMS from a patented concept to a widespread solution. Feel free to reach out if you have ideas, questions, or interest in partnering – I’m eager to hear from you.

Together, we can transform noise pollution from a nuisance into a valuable resource. Thank you for reading, and stay tuned for more updates as we advance this exciting technology!

For those interested in the technical details, you can read the full patent publication (WO2025128348A1) on WIPO or on Google Patents.